TECHNOLOGY + INNOVATION

How We Do It

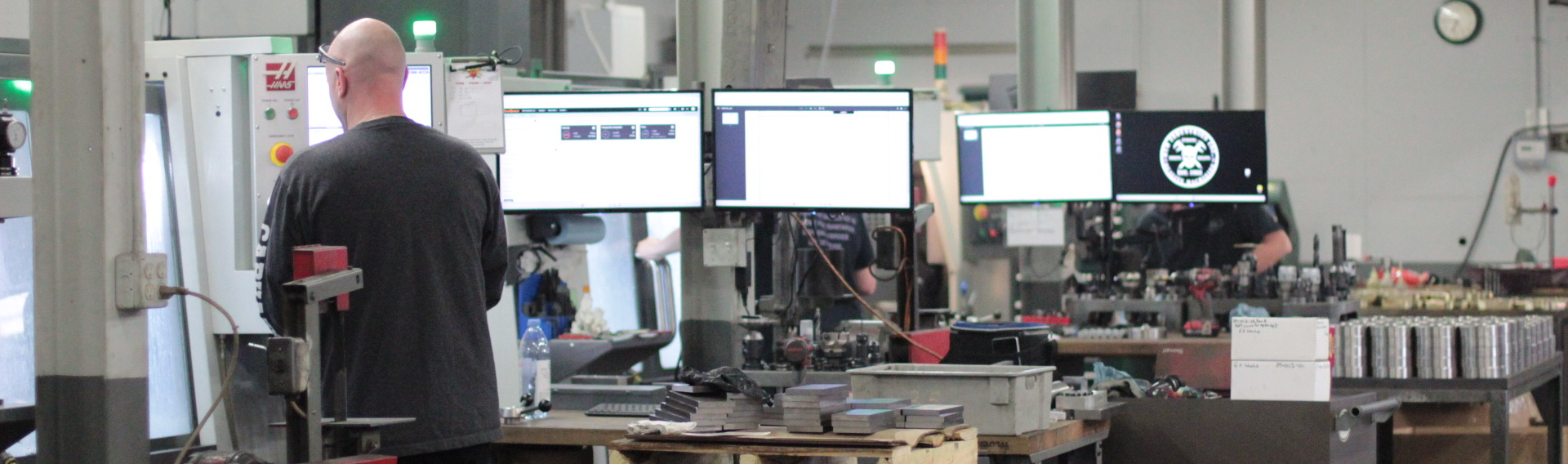

With over 60 years of history, BTM has embraced innovation, seamlessly merging decades of machining expertise with cutting-edge technology. We embrace technology as a catalyst for progress, continually improving our processes to exceed customer expectations. Our commitment to innovation extends to adopting a paperless workflow throughout the company. While our roots run deep in the traditions of machining, our embrace of technology propels us forward into the future.

ProShop ERP System

Paperless Parts Quoting System

Romer Absolute Arm Portable CMM with Verisurf Software

Fusion 360

MasterCam

1Factory to create balloon drawings for quality inspections